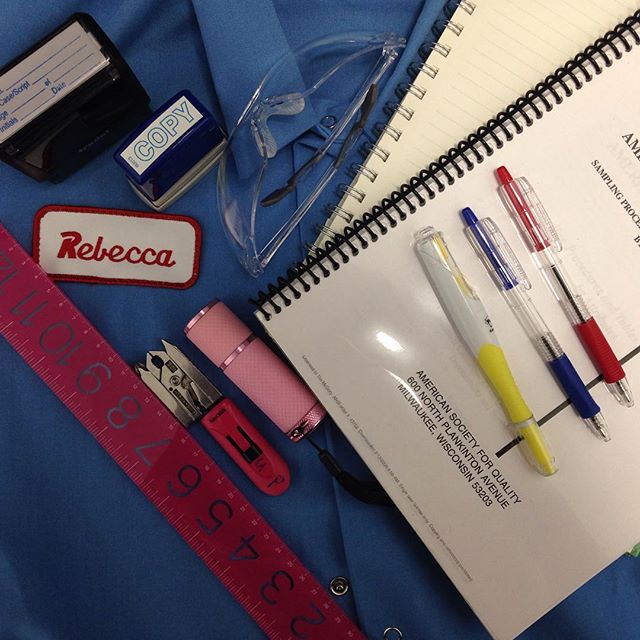

Now that you know a bit about me (yes, I’m real), here’s a bit about what I actually do. I am an Independent Consultant with my own business, where I am typically cast in the roles of Senior Project Manager and Principal Consultant in Commissioning, Qualification, and Validation (CQV) within life sciences engineering. These roles allow me to bridge the gaps between engineering, technology, and regulatory compliance, ensuring that the products we develop meet the highest standards of safety and efficacy. Functionally, I am at the intersection of engineering and defense lawyer. Also known as “Chief Chaos Coordinator”, “Project PITA”, and “Pink Swiss Army Knife”.

What is CQV?

CQV stands for Commissioning, Qualification, and Validation. In the life sciences sector, it’s a critical process that ensures all components involved in manufacturing regulated products comply with specific legal and regulatory standards. As a CQV professional, I lead technical and Quality efforts on capital projects across pharmaceuticals, medical devices, nutrition, and cosmetics. My role is to ensure that everything from the ingredients to the facilities, utilities, systems, and equipment (FUSE), to the final products, and distribution of those final products adheres to stringent regulations. Literally, it’s my job to make Quality Assurance happy. We all know that QA, in any industry, is like a Southern mama. When QA ain’t happy, ain’t nobody happy.

Key Regulations Governing CQV

In the United States, the Food and Drug Administration (FDA) oversees the regulation of these products through the Code of Federal Regulations (CFR). Here’s a closer look at some of the key regulations:

- 21 CFR 210 and 211:

- Manufacture and Distribution of Regulated Goods: These regulations provide the guidelines for Good Manufacturing Practices (GMP) for drugs and finished pharmaceuticals. They ensure that products are consistently produced and controlled to quality standards.

- Components Covered: Everything from the ingredients and excipients to the final product must comply. This includes rigorous testing, quality control, and documentation processes to ensure product safety and efficacy.

- 21 CFR 820:

- Manufacture of Medical Devices: This part governs the quality system regulations for medical devices, ensuring that they are safe and effective for their intended use. It covers aspects such as design controls, production and process controls, and corrective and preventive actions.

- Importance: Compliance ensures that medical devices meet the required standards before they reach the market, safeguarding patient health and safety.

- 21 CFR Part 11:

- Computer Systems and Automation: This regulation governs electronic records and electronic signatures. It sets the standards for the use of electronic systems in managing data, ensuring its integrity, security, and traceability.

- Relevance: In today’s digital age, adherence to Part 11 is crucial for maintaining the accuracy and reliability of electronic data used in manufacturing and quality assurance processes.

Global Compliance

While the FDA regulations are critical in the USA, my work also involves ensuring compliance with international standards, including:

- European Medicines Agency (EMEA): Governs the regulation of medicines within the European Union.

- Japan Ministry of Health, Labour and Welfare: Oversees the safety and efficacy of pharmaceuticals and medical devices in Japan.

- Brazil’s ANVISA: Regulates health-related products, including pharmaceuticals and medical devices, in Brazil.

- International Council for Harmonisation (ICH): Provides guidelines that ensure quality, safety, and efficacy of pharmaceuticals across different regions.

- Health Canada: Regulates drugs, medical devices, and other health products in Canada.

Day-to-Day Responsibilities

As a CQV professional, my daily responsibilities include:

- Project Leadership: Managing capital projects from inception to completion, ensuring all aspects meet regulatory requirements.

- Technical Oversight: Providing technical guidance on engineering and validation activities, ensuring compliance with regulations and industry standards.

- Risk Management: Identifying and mitigating risks associated with manufacturing processes and systems.

- Documentation and Reporting: Ensuring thorough documentation and reporting to demonstrate compliance with regulatory standards.

- Training and Development: Conducting training sessions to ensure that all team members understand and adhere to regulatory requirements.

The Impact of CQV

The work I do in CQV has an unmistakable impact on public health and safety. By ensuring that all manufacturing processes and systems comply with stringent regulations, consumers are protected from potential risks and safe and effective products are delivered. There was an ad from Eli Lilly in the 1980s, stating “The one you take is never tested.” To ensure that product’s safety, identity, strength, purity, and Quality, robust CQV must be in place. You can think of me fondly when you reach for your bottle of ibuprofen this month.